[Audio distortion occurs throughout the interview.]

Stephane Groueff: Recording interview with Mr. Leon Love at Oak Ridge July 15, 1963. Mr. Love works with Y-12.

Would you mind repeating sort of some of the characteristics of Y-12, some of the figures? For instance, how many buildings? How many magnets? How many Alpha [calutrons] and Beta [calutrons]? How many units in each?

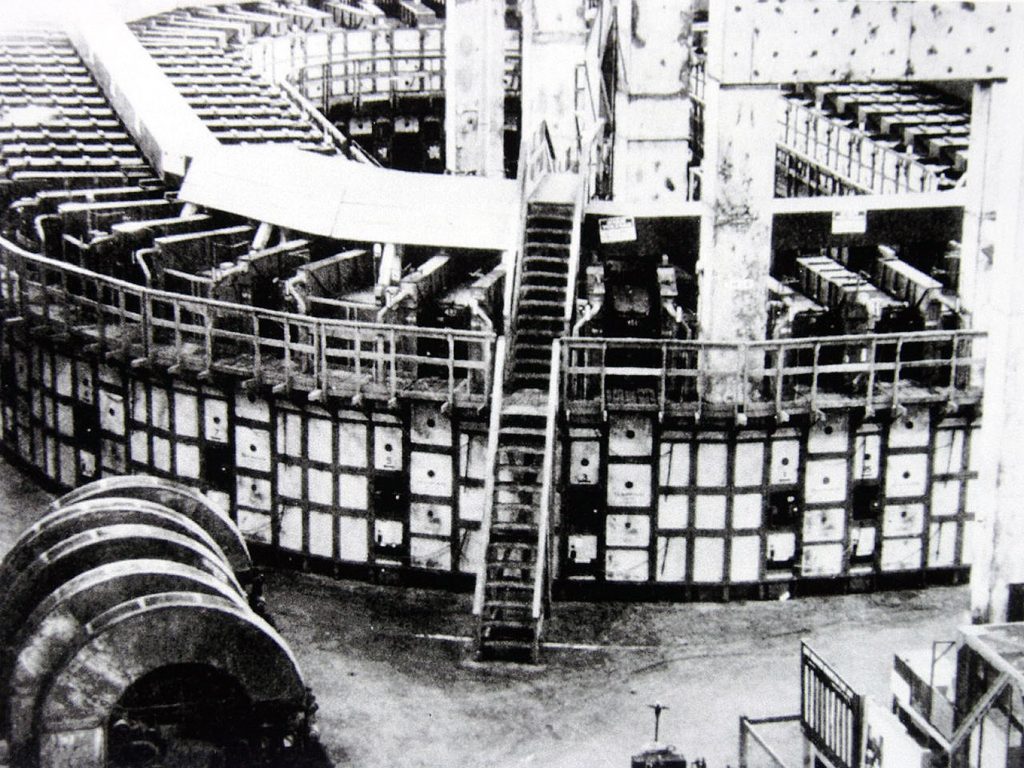

Leon Love: There were five buildings containing the output separators, and there were nine tracks total in these five buildings.

Groueff: Four buildings with two tracks, and one with one.

Love: Right, and there were ninety-six separators in each track.

Groueff: A “separator” is a calutron?

Love: Right.

Groueff: Ninety-six calutrons in each track. So I have to multiply ninety-six nine times. That’s practically, I don’t know, 800 and some odd calutrons. Now what is the Alpha 1 and the Alpha 2?

Love: The Alpha 1 calutron was different. It was characterized by the fact that it had what is called a cold source. The ion gun or ion source was a ground potential. The Alpha 2 had the ion source at high voltage, something like thirty-five to forty kilovolts above ground. The Alpha 1 was the older model.

Groueff: But Alpha 2 also started from natural uranium?

Love: Yes.

Groueff: So they more or less had the same function?

Love: That’s right. The one other difference was that the Alpha 1 had two ion guns or ion sources. The Alpha 2 had four.

Groueff: Four each?

Love: Yes. We would say four arcs.

Groueff: Four arcs and four receivers for each?

Love: Yes.

Groueff: So multiply the 800 or 900 calutrons by four. So it’s in the thousands actually. You had thousands of those receivers, the pockets?

Love: Right.

Groueff: Now I wasn’t quite clear—those envelopes, the receivers, were they made out of graphite or out of steel that was plated?

Love: They were made from graphite and copper primarily. The plate that sealed the vacuum port was a nonmagnetic stainless steel plate. The collecting pockets themselves were graphite or copper. Actually, in almost all cases, the ion beam [00:28:11] was allowed to strike a graphite collector because it doesn’t erode. The ion erosion wasn’t so severe.

Groueff: I don’t understand. Dr. [Clarence] Larson explained that the ion was hitting steel in the pocket with such strength that it got embedded into the steel at the beginning. That was a complication. That’s why they had to plate it with copper.

Love: Would you like to see some of them? I think I have some left.

Groueff: Yeah. I would love to see it. You have the real receivers?

Love: In the salvage yard, we retained enough separators to expand our facilities to I think twenty more separators. So I have the spare parts.

Groueff: That will answer my question. Now the Betas, how many were there?

Love: There were four buildings, each containing two tracks. Each track contained thirty-six separators, and each separator had two arcs.

Groueff: Two beams going simultaneously.

Love: Right. Then each separator had two ion sources, two parts.

Groueff: They were constructed at the same time as the Alpha buildings, more or less?

Love: They were constructed concurrently. Of course the very first building was the pilot plant that contains two separators of each size. The sizes of these machines are referred to as twenty-four and forty-eight inch radius machines, meaning that the ion travels on the arc of a circle of twenty-four inch radius, or on the arc circle of forty-eight inch radius. The advantage in the larger radius being that the separation, we say dispersion, between the two masses, it is twice as great with the forty-eight as it is with the twenty-four.

Groueff: I want to ask you about the magnets. You said it was 3,000 tons? Was that the figure?

Love: Yes. The Beta magnet, which is a small one, the entire complex weighs approximately 3,000 tons.

Groueff: And the Alpha?

Love: I don’t know what the weight of the Alpha is, but it must be many, many times. Because, you see, the Alpha system was twice as large in all directions.

Groueff: You think the magnet of Alpha would be at least twice as big?

Love: Oh yes. Maybe four times.

Groueff: So it would be about 12,000, 10,000 pounds?

Love: I would estimate the total magnet complex to weigh probably 10,000 tons.

Groueff: They had never been built before, such giants?

Love: No.

Groueff: How did they arrive here? By parts?

Love: They arrived by separate components. That is, the vacuum tank that is set between the pole pieces of the electromagnet was just shipped in. First the track was built and the electromagnet coils were set in place. In the Beta system, the coil winding, the actual conductor, had between twelve and eighteen tons of silver in its winding, or, when copper became available, copper. The Alpha coils had between fourteen and twenty-one tons of silver in the coils. Most of the Alpha coils were of silver.

Groueff: While they were mounted here, were they heavily guarded by security?

Love: During the time they were mounted or assembled, I would say connected and set in place, they were carefully guarded by the guard force. All the filings that were dropped from a drill when the bus bars were being bolted together, the filings from the drilling operation would be swept up and accounted for. The silver bars were beautiful exhibits. They were about three-sixteenths of an inch thick and about three or four inches wide. Great, long, beautiful.

The current required to excite the magnet of a Beta magnet in one track was between 4,000 and 5,000 amperes at about 350 volts. So you can see the power required. The power supplies for the Beta calutron was about sixty-five kilowatts for each of the separators.

Now there were many auxiliary power supplies in addition to this, but the cubicle that the girls operated was a sixty-five kilowatt power supply and had voltages and currents ranging from—there was a better way to say this. It had power supply components that would supply, say, 500 amperes at three volts for each of the parts. One supply had the capability of supplying 50,000 volts positive potential at one ampere for the Beta and two amperes for the Alpha. Each cubicle had a power supply that would supply up to 50,000 volts negative at half an ampere for the Beta and one ampere for the Alpha.

Groueff: So the whole operation required a tremendous amount of power. It all came from TVA [Tennessee Valley Authority]?

Love: Yes. I diverted from where we were talking about setting tanks in place. The way those tracks were constructed, of course after the foundations were laid, they set the magnet coils in place and the cores. The magnet coil itself was one large continuous conductor that was in sort of the form of a “D”. The cross section of this container was about two by two feet, I guess eighteen inches maybe by two feet, and this contained the silver windings. Then this coil had a total diameter of, for the Alpha, something like twelve or fifteen feet.

The center part of it, the part that was bare and where air would fill it if you didn’t fill it with iron, was filled with iron sheets because magnetizing forces are conducted better through iron than through air. When these were all set in place, then the vacuum tanks were set in place, then the diffusion pumps were put in place. Now, the diffusion pumps were an Alpha system. There were two or three depending on whether it was early models or late models. The diffusion pumps had a pumping capacity of 10,000 to 15,000 liters per second each at the pressures that we operated, which was about 0.02 or 0.03 microns per pressure.

What I failed to convey to you is that if you looked at the core, the container for the winding, it would be a box, say eighteen by twenty-four inches, and would be continuous with an outlet here and here where oil was forced in here and taken out up here. Now that box had this large open space and that is a resistance, offers resistance to the magnet lines. So they put iron strips in here. You see then the separator was here. Now that was an air gap, too. You wanted no air in this region. Then the one next to it was a coil and it would have the iron. I think what we do is just go look at some of these.

Groueff: I think when I see it I will have a better idea. Now I wanted to just discuss some generalities. There were no heavy parts coming from Milwaukee, from Allis-Chalmers [Corporation], something in the hundreds of pounds or thousands of pounds?

Love: Not as a unit.

Groueff: They all came by component?

Love: Right. The Beta tank weighs about 18,000 pounds. The walls are about four inches thick, and this is to withstand the atmospheric pressure. If you look at the size of them, when you evacuated, you realize that it takes a lot of support to prevent it from collapsing. It couldn’t collapse and it couldn’t distort.

Groueff: So it had to be very strong?

Love: Yes.

Groueff: About this vacuum, I read in this book by [George O.] Robinson, The Oak Ridge Story, and it gives some figures. It says, “Pumping equipment was designed and built capable of producing a vacuum thirty million times that commonly used in standard power plant practice.” It sounds a fantastic figure, no? The calutrons don’t operate on a very high—

Love: It is about one, two, or three times 10-5 millimeters of mercury. It is one-hundredth of a micron, whereas a high vacuum today is generally thought of in terms of two or three orders of magnitude lower than this. In other words, one ten-thousandth of a micron.

Groueff: In other words, the vacuum standards in this particular plant were not that spectacularly extraordinary?

Love: I suppose it was considered a pretty good vacuum at that time. Although there was vacuum equipment that would go lower than that, certainly one or two magnitudes lower than that at that time. One of the things that was fantastic about it was the pumping speed, which was something like 5,000 to 20,000 liters per second at the pressures that we were operating at.

Groueff: That was to create the vacuum?

Love: That was to maintain the vacuum. Understand that when I say 5,000 to 20,000 liters a second, I am talking about at a pressure of one-hundredth or two-hundredths of a micron. The total volume of air is not as much as that sounds.

Groueff: So that was rather new and unusual?

Love: That was. One interesting concept: atoms were put into the collector literally atom by atom, and I think it figures out to be something like eighteen billion atoms per second. If you use that number, we need to check it for sure. It might be off a few billion.

Groueff: Atoms are atoms. Finally after three days, you said in each collector they will have a few grams, about ten grams or something like that?

Love: Tens of grams. A few tens of grams.

Groueff: Not an entire gram? Milligrams or centigrams?

Love: A few tens. That is, some number, like one times, or two times, or three times tens of gram, depending on how the run went. It would usually be more than ten grams of material. Now this had to be divided into the natural abundance, or the abundance in the charts. For instance, if you got out ten grams, that would be 10,000 milligrams, but if the starting feed was seven-tenths of one percent, you had only seventy milligrams of uranium-235

Groueff: What I mean is the material you collect, if you put it on a scale, it will be about ten grams or twenty grams or something. What is contained in the envelope? When you pour it out it, is about ten grams material?

Love: Are you talking now about the [uranium] 235 or the [uranium] 238?

Groueff: All of it. After three days you stop it and you take this envelope which is labeled “enriched.” Now this envelope, you pour it out. I want to find out whether it will be something visible or something in the magnitude of grams.

Love: It would be between twenty-five and fifty grams, usually.

Groueff: So it’s quite sizable. That makes quite a lot of powder.

Love: Right. Of course, uranium is pretty dense.

Groueff: It doesn’t mean that it is uranium-235. Out of this twenty-five grams, it goes to the chemical process, and they will take the enriched material out of the—

Love: It will be in two parts. One would have the [uranium] 235 and one would have the [uranium] 238, and only seven-tenths of this amount would be—

Groueff: [Uranium] 235. Because it is still not enriched enough.

Love: Right.

Groueff: What I was trying to find out is what the eye meets when you take it out of the pocket. I wanted to find out whether you see just the one or two little specks of powder, or you see ten grams of powder, or twenty-five. It is a sort of mixture with graphite also, I understand.

Love: Yes. Graphite and Copper.

Stephane Groueff: Now what would be the start-up preparation when you start from zero? How do you start an, Alpha for instance? I want to describe this scene, in which you start first the generators and then the vacuum, or how does it work? You just switch a button and the whole process starts?

[George Banic enters conversation.]

George Banic: Assuming that all components are already fabricated, they are installed into the vacuum chamber, and then the proper valves are manipulated and the system is evacuated. Since this is one out of many separators in the large magnet, you have to assume that the magnet is turned on. Adjacent to this, there are separations already going. You might say the first thing you do, the magnet would already be turned on. If it was the very first unit, you would turn the magnet on. If it is no longer the very first unit, then the magnet is already on.

Groueff: How do you turn the magnet on?

Banic: By starting a motor generator.

Love: 2,500 horsepower or 5,000.

Banic: Depending on which building you were in. The generator, of course, is turned on. The value electronic regulation is set to the operating level and then essentially forgotten. It operates at that level twenty-four hours a day, seven days a week and is never turned on except for power failures and accidental shutdowns. So the magnet essentially can be forgotten as far as the operation is concerned, and soon taken for granted. Then equipment is put into the vacuum chamber, as I mentioned, and evacuated. Once a sufficient vacuum—

Groueff: The vacuum is obtained after you turn he magnet on. First the generators and the magnets, then you create the vacuum. How long does that take?

Love: The base pressure required thirty minutes to an hour.

Groueff: So it’s not just a matter of a few seconds?

Banic: No. It takes a while.

Groueff: For the Alpha for instance, about one hour, roughly?

Banic: That’s for the base pressure now; you are still not ready to go. It is probably closer to eight hours before you can go to the next step. Then the next step is, you turn on the accelerating voltages.

Groueff: You can’t produce those at the beginning?

Banic: You have to wait for a good vacuum, so you don’t have this terrific sparking. Now, you will have some sparking. Now you have the procedure for the interval, which is known as the “baking out”. You have the good vacuum, and you turn on the accelerating voltages. There is a small amount of sparking, but the system is now being baked out. This can last for a matter of hours.

Groueff: Just putting the accelerating voltages?

Banic: Yes, just putting on the accelerating voltages. They’re turned on immediately.

Love: They’re turned on at a low value. During this period, they have to be watched very carefully, and during this period they have what they call start-up crews, people who were sensitive to the effects of electrical discharges on the equipment. This was called the “bake out” period.

Banic: You literally were baking out. You were heating things up. As it was being heated, gas was evolved, included gasses inside the components.

Groueff: Do you change the voltage?

Banic: You start at a lower voltage. Almost always you will have a certain amount of sparking, electrical discharge. Then as the components are heated, due to the sparking and the gas driven off, then the voltages can be raised.

Groueff: And the sparking disappears?

Banic: Well, the sparking will disappear eventually.

Love: The process this time is called “outgassing”. You were outgassing the equipment, driving the occluded gasses out.

Banic: Cleaning the system essentially, inside.

Groueff: And that can take hours? Seven or eight hours?

Love: Actually it turned out that it, in part, was a function of the humidity. I have plots and graphs on the effect of humidity on the start-up. If it was a rainy day, those units took a long time. If it was a dry day, it would go quick.

Groueff: After eight hours, the right voltage is reached and all of the gasses are—

Banic: Gone. The pressure meter has come back down. Your indication during this period is your pressure meter. It tells you the conditions of the vacuum inside of the separator. When the system is thoroughly outgassed, then you will notice the pressure meters have come down to what would normally be the operating pressure, and the accelerating voltages will stay on.

While this is going on, there are electrical protection systems. On these discharges, it shuts the machine down and starts it up. This part is automatic; it is a recycling system. So then once the pressure has come down and they are able to hold the voltages, then there were different techniques on start-up. Usually the arc voltage and the filament was turned on, and the support gas was introduced.

Love: The support gas came after we started and stabilized.

Groueff: What is a support gas?

Love: This is a gas that lets you get the machine in operation. First, with gas like nitrogen, we used nitrogen a lot, or argon. With uranium, though, we just heated it up. You started at a temperature at about fifty degrees centigrade and raised it a certain number of degrees, say ten degrees, every so many minutes, five or ten minutes, depending on how the pressure went up. This depended on how well the material was protected from moisture when it was made. If the moisture content of the feed material was low, then this time was short. If it was high, this time was long.

Groueff: So the uranium gas, uranium tetrachloride, was introduced only after this period of several hours.

Love: That’s right.

Groueff: How does it look? Say we reach this voltage and the pressure is down—

Love: This is a compound. It is actually inside the separator when the separator is installed into the vacuum system. It has a very low vapor pressure at room temperature. It is a form of a compound; it’s a salt really.

So once we reach the proper vacuum and the proper voltage, the arc voltage is turned on, the filament is turned on, and we are ready for the ionization mechanism to take place. All we are lacking now is something to ionize. So we turn on the temperature control system and we raised the temperature of this compound. The temperature comes up slowly until it reaches a sufficient vapor pressure, and now we have the gas in the ionization chamber.

Groueff: That also takes hours?

Love: Hours. It may be done concurrent with the voltage.

Groueff: Is it a different electric system to heat?

Love: Yes, and it heated the charge bottle to about 400 degrees centigrade.

Groueff: And only then do you start the beam arc?

Banic: The arc itself, yes. In other words, the arc you see will be small because as its vapor begins to enter the ionization chamber, then the temperature goes up. You get a larger increase in vapor and the ionization mechanism.

Love: It actually worked in practice more like a flash. You get the small emission or a small arc. There was a term that referred to when it was coming into operation: “My J’s are struck.” The arc was referred to as a “J”. All components were coded and the arc was called the “J”. And the girl would say, “I’m striking my J.”

Banic: Which simply means that there was now sufficient vapor to strike the arc, the ionization mechanism was now underway.

Groueff: When you “strike the J”, it means the whole beam is going now, that is the beginning of the real operation?

Love: And that’s when you see the arc from one side to the other. Then there is a few moments of chaos when the high voltage will not hold its sparks. We say, “It goes into a flurry.” After a while the high voltage will hold and now the beam is coming out.

Banic: This is strictly because of pressure.

Groueff: I had the wrong impression that from the moment you first turn on the generators to the separation, the arc, it took one half hour. Now I see that it takes probably a whole day.

Banic: Sometimes a whole day, yes.

Groueff: You say about one hour for the program, then eight hours for voltage, then a couple of hours of the temperature. It is a good twelve hours, no?

Love: That’s right. At least twelve hours.

Groueff: Because I am trying to use it as an example to describe this scene, over the first start-up. I will describe it, and then everything stops. You remember you were telling me of the first failure. Now, you did all of these things that you describe, and the arc started functioning? The separation was all right for a few minutes or hours before it stopped?

Banic: I don’t know. See, I never had worked in any of the production buildings.

Love: Well, I have. The time from when the run was started until the time it would terminate was in order of seventy-five hours.

Groueff: What I will do is, I will make a scene, a chapter. I will describe the start-up with the detail you gave me now, and then say that, after a few hours or days or so, suddenly a reason that at the beginning you could not know, everything stopped. Now, how can I describe the failure? What happened exactly? Is it like a power shortage?

Love: The magnetic field was the component that was affected.

George Banic: Yeah.

Love: When this started shorting out, the beam started straying.

Groueff: I see. So sort of the beam—

Love: Disappeared. Essentially, it just disappeared from its space.

Groueff: Is it like when you water with a hose, the water goes in a beam. Then you shut or you diminish the water, it goes—?

Banic: Except just the opposite.

Groueff: It goes strong?

Banic: It would go stronger.

Groueff: It would go stronger.

Banic: Without the magnetic field, it would tend to go to a straight-line rather than hit into a bucket.

Groueff: The water and then the—

Banic: The analogy is good except the tendency is to go to a straight-line, and it takes a strong magnetic field to pull it down.

Groueff: I see.

Banic: It works the opposite from the gravity effect on the water you are trying to send it through.

Groueff: The trouble was that suddenly and you realized that the beam was not curved nicely or as expected, but started going too strong and straight?

Love: As I remember the stories, it was more like the man having a hose that held it on a spot and then it began to tantalize you, moving it just a little bit. Not enough that you knew for sure, that that was what was wrong.

Banic: That’s a good analogy.

Groueff: Yeah.

Love: Then it got worse, he got more careless or he got drunk, that is more likely.

Groueff: So the worker starts spraying all over the place.

Love: Everywhere. But it was always in one direction, as George says, towards the straight-line.

Groueff: Then certainly everything stopped.

Love: Well, again we began to find out.

Banic: There are side effects there. Once you lose the magnetic field, then you cannot maintain these high voltages in the source. Then you begin to get discharges and the electrical protection system will go out, will go down. It is just a complete deterioration of all the facilities involved.

Groueff: Finally, everything will stop? I mean, the magnetic field will disappear?

Love: Yes.

Banic: And the exonerating voltages will turn themselves off. The ion mechanism will stop and the ion meters that indicate the ion current will just go to zero.

Love: But it is not a malfunction of the electrical components. It is more as though the automobile ran out of gas. The carburetor would still work, the battery would still go. Actually, that is really not a good analogy because you could just not keep the voltages on.

Banic: You see, the things are so interdependent. The high voltages are dependent with the magnetic field. Without the magnetic field, you cannot maintain the high voltage gradients between the accelerating systems, because the gradients are restrained by the magnetic field.

The ionization mechanism is restrained—or the ionization mechanism is actually confined by the magnetic field. So that when you lose the magnetic field in addition to losing the direction in which the ion beam is going, you also lose the concentration of ions that make this beam in the first place.

Groueff: Right.

Banic: And also you lose the ability to maintain the voltages, the high voltages in the accelerating system.

Love: The whole system essentially just deteriorates. Not because of any failure of any component from this respect, it is just that they all fit into a neat system. Any portion of that system is disturbed, this disrupts the imbalance of everything else.

Groueff: The final result will be what? That there will be no beam?

Banic: There will be no beam. The system will be shut down because there is electrical protection circuits that shut it down when something like this goes wrong.

Love: The miracle of this process was that there were so many components that had to function properly, simultaneously. To get all these things going at the same time, so that you could keep it going for a period of time, was quite a miracle.

Groueff: Quite a miracle.

Love: Yes. It is almost like life itself, in that the minute you start it, there is a period during the start-up when you are bringing it into the peak performance, just as you are growing up. Then deterioration sets in, and you know there is going to be a cessation in the performance in a little while.

Banic: It has to be a balance system. Anything that goes out of balance affects all other components of the system. For the protection of the equipment itself, it is usually all electrically interlocked so the whole thing shuts itself down.

Groueff: That was the lowest moment of Y-12? General [Leslie] Groves arrived and [Ernest] Lawrence was here, probably. You said that some people said it was sabotage at the beginning, and then they opened it and saw all the grit.

Love: That is right.

Groueff: And the rest, and had to send the magnets back to Milwaukee.

Banic: No, no they were cleaned here.

Love: It would have been almost impossible to send them back.

Banic: Yeah.

Love: Because in the first place, they were all set in the track. You could have sent them back there.

Banic: You could have, yes.

Groueff: They did, because General Groves’ book says that they sent them to rewind even the silver bands.

Banic: That makes sense.

Love: I did not understand that.

Groueff: There is a full explanation and as you said, it is not just one unit that you are moved, but parts of it probably. But he says that also they rewound them, the silver bands, with the little bit larger—

Banic: Spacing.

Groueff: Spacing.

Banic: For insulation, that is quite possible.

Groueff: And also installed filters and oil system.

Love: He would know.

Banic: It could be that when this shorting took place, it damaged the electrical insulation and the coils had to be rebuilt.

Groueff: That happened over several weeks, no?

Love: This is quite possible, because as I remember they barricaded it. They secluded it and nobody could go in that work area and the personnel was—

Groueff: Personnel reported to work every day.

Love: Oh yes.

Groueff: In the same building.

Love: Right.

Groueff: I understand they showed them movies and played chess?

Banic: They were supposed to have been in a training to understand their program a little more, I would think. Because they had a continual training program going on all the time.

Groueff: They had no idea what happened. They knew it just did not work, and they had to report every day.

Love: They knew their cues were not peaking. The meter reading—the meter that read the line curve that went into the collector—was referred to as a Q-meter.

Groueff: Q, like the letter Q?

Love: Yes. The common term was, “Peak your Q’s.”

Groueff: Peak your Q’s.

Banic: To make that meter that detected the ion beam to read the highest bustle, because then it is the measure of the output. You had to peak them, because you naturally wanted the highest meter reading, which means you had the largest quantity coming in to the collector.

Groueff: It has to go to peak?

Banic: To a peak, yes.

Groueff: The girls were saying, “I peaked my Q?”

Love: “I struck my J.” “My K has burned out.”

Banic: He might not get involved in all those code terms.

Groueff: Probably one or two, just to get an idea. When the trouble happens, the girls could not peak their Q’s.

Banic: The Q’s, that is right. From that it was obvious that something was wrong with the separator.

Love: This is film.

Groueff: That is the description of the start of trouble.

Banic: Right. Track one ran for about one month from the middle of September to the middle of October 1943. When one coil developed short circuits from iron filings and the slag, which we described, from the cooling system, it burned a hole in the coil casing.

Groueff: Only in one coil?

Banic: Only in one coil.

Groueff: One coil. So it was not a general trouble?

Banic: No, this is just in one coil. The track was shut down for approximately six weeks to remove this coil and to replace it with one, which was to be used in track four at a later date.

Only a few days after it was reinstalled, during the month of December, the complete track was shut down because of the same cause—iron filings and slagging shorted out the complete second track one. Then the emphasis was made to shift to track two, since it already had its regular schedule.

Groueff: Was it closed? That was not only one coil, but all coils?

Banic: All coils.

Groueff: Because in the meantime, the oil was circulating?

Banic: Was circulating and carried these metallic particles to all of the coils.

Groueff: And you said that happened after a few days of operations?

Banic: After a few days of operation.

Groueff: Actually, when you put at least one day to a start-up and a couple of days, probably it worked, that would be a few days.

Banic: That is right. It probably would be say something like three, but maybe it might be as much as a week or two weeks, but a few days is all right.

Groueff: It did not come suddenly one second, but it started the beam starting having a strange way?

Banic: That is right, and it would be one separator at a time was probably affected. Maybe one and then two and three and then maybe a half a dozen, so it would be gradual.

Groueff: Deteriorates, and then suddenly the whole thing is shut down?

Banic: Shut down. Then with the emphasis on track two, we had all these people coming to work— and then this is where you already have the information about showing movies and all for twenty-four hours a day, since people were clocking in every eight hours to come to work, and that was three shifts. Nothing for them to do.

Groueff: They were coming to the buildings?

Banic: To the same building, yes.

Groueff: And checking in?

Banic: Checking in and checking out. Then the track one was removed, all the coils in track one were removed and sent to Allis-Chalmers for rebuilding. While they were, the oil filters and other protective strainers were installed in the magnet system.

Track two was ready to go in April of 1944, which was really the first one to be in complete operation, so that meant that from [inaudible]. At the time that track one actually shut down, it was about two-thirds in operation. How many separators were there?

Love: Ninety-six.

Banic: Ninety-six. So there were two-thirds of the ninety-six were actually in operation when the track was shut down because of this major difficulty.

Groueff: So that means that it was a major—?

Banic: It was a major catastrophe from that standpoint, a disaster.