The B Reactor at Hanford was built and operated by DuPont and was the world’s first production-scale nuclear reactor. B Reactor was the first of three plutonium reactors constructed in the 100 area during the Manhattan Project.

Design of the B Reactor

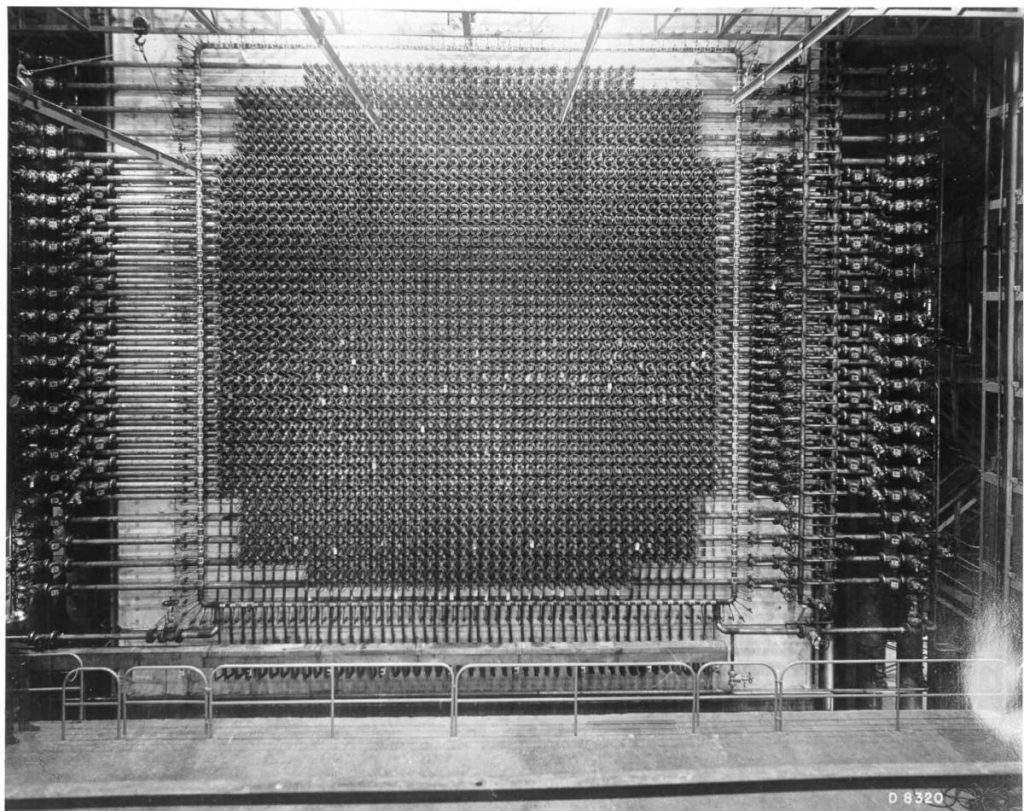

The design was based on the success of Enrico Fermi’s “Chicago Pile I” in December 1942 and a pilot plant, the X-10 graphite reactor, in Oak Ridge, TN that began producing plutonium in November 1943. B Reactor was a 36-foot cube built of graphite blocks with a matrix of holes for the process tubes that held the uranium fuel and the control rods.

B Reactor was designed to produce 250 million watts, more than a million times the Chicago Pile I. While the X-10 pilot plant was air cooled, B reactor was water cooled. There was no time to build another pilot plant or rigorously test engineering solutions to the many first-of-a-kind problems. DuPont engineers had to work quickly to translate the Chicago physicists’ ideas into blueprints to keep ahead of the construction crews at Hanford. The fuel elements were loaded into the reactor. At full capacity, workers had to load over 60,000 fuel elements into the reactor’s 2,004 process tubes.

After an average of 100 days in the reactor, a fuel element would be sufficiently irradiated to be removed . The fuel elements were ejected from the rear face of the reactor where they fell into a 20-foot pool of water. Here they cooled off for about 90 days until they were ready to be shipped to the chemical separations plant in the 200 area. B Reactor was equipped with multiple redundant safety systems. During routine operation, the reactor was controlled using nine neutronabsorbing control rods inserted horizontally into the reactor.

Reactor Safety

B Reactor also had 29 vertical safety rods that could be quickly dropped into the reactor if the horizontal control rods were insufficient. As a last resort, a mechanism above the reactor could drop small boron balls into the reactor. These balls would stop the reaction and could be vacuumed out later so as to not permanently damage the reactor. Operators had to constantly monitor more than 5,000 instruments, most of which were located in the control room. Many of these devices had never been used in an industrial setting before. The main control panel was staffed around the clock. The reactor core generated a tremendous amount of heat.

Cooling the Reactor

Water pumped from the Columbia River was filtered, treated and stored in facilities near the reactor. To cool the reactor, some 30,000 gallons of water were pumped through the reactor every minute. The water was channeled through thin passages between the process tube and fuel elements.

Afterwards, the cooling water was stored for up to four hours in basins to cool down and then discharged back into the Columbia. Nearly 75 percent of the electricity in the 100 Area went to pumping and processing water for cooling. B Reactor, once threatened with demolition, is an icon of the Manhattan Project at Hanford. Today visitors can tour the original reactor and listen to Manhattan Project veterans describe the facility and their experiences there.