[At top is the edited version of the interview published by S. L. Sanger in Working on the Bomb: An Oral History of WWII Hanford, Portland State University, 1995.

For the full transcript that matches the audio of the interview, please scroll down.]

Book version:

I went out to the Du Pont Experimental Station in 1929, after I received my doctorate from the University of Illinois. I was a physical chemist and rather long-haired I would say. Working with chemical engineers was, well, some-thing outside my field. After I learned that the only real difference between a physical chemist and a chemical engineer was that they spoke in pounds and we spoke in grams, there was no problem.

My first assignment was under Crawford Greenewalt, who was directing a modest-sized group of chemists working in organic synthesis and separation of products. Crawford went up the ladder relatively rapidly and soon became assistant director of the laboratory. Then the war was coming on, it was 1939. When Du Pont got into atomic energy, Crawford Greenewalt was one of the top people, and he took certain of us along with him, people he knew and had worked with.

In November of ’42, Crawford called a few of us together, Lom Squires, Monte Evans, Hood Worthington and myself, some others, and said, “I am going to describe to you people something that is heresy to chemists. We are going to make a new atom, on a scale of pounds per year. That new element is plutonium.” To persons who were chemists all their lives, that was heresy, absolute heresy. If he had said micrograms, it would have been no problem. He described what had been done by Seaborg and Compton and Fermi and the whole works. But, nothing would be done for now, go back and continue working in nylon, he told us. Crawford saw the Chicago reactor go critical in December and he came back all excited, and about at this time I was taken out of nylon and put on this development full time as the liaison between Du Pont and the Chicago group in the area of physics and reactor control.

That‘s when I met Fermi. He let me run the reactor in Chicago after I expressed an interest in control, how we could keep things from getting out of hand. Control is no problem, Fermi said. “Sit down here at the controls,” he said. I leveled it out after three or four minutes and his words were, “You are indeed a very careful young man.” I wasn’t much younger than he. I was 36.

Things happened rapidly after that. Du Pont was asked to build a plant and operate it. In Wilmington, I was directing a group of physicists and engineers, including John Wheeler. We were greatly concerned about criticality, which was related to the number of atoms that were inside a reactor that didn’t contribute to the nuclear reaction itself. Obviously, we had to have water in there, and aluminum, we had to have control rods. We were operating on a very thin margin of criticality. “Excess k“ is a term I will bring in now and that is the percent of neutrons that are in excess of those needed to maintain the reaction. That number must be a small positive number if the reaction is to sustain itself. .001 is enough but you won‘t do very much at that rate. It has to be over 1.0, enough over 1 to take care of the materials that absorb neutrons without contributing to fission.

John Wheeler was concerned about the effect of fission products on the nuclear reaction. If these substances formed when the U-2 3 5 atoms split, they would stop the reaction because they absorbed too many neutrons. We had a way of measuring that probability of capturing neutrons, called a cross-section. We called that measurement unit “barns.” The largest cross-section known at that time was about 50,000 barns. I am jumping ahead of the story but xenon-135 formed in the first nuclear reactor at Hanford had a cross section of about 3.5 million barns. Completely unheard of, and unpredicted.

The first nuclear reactor at Hanford died almost right away. John Wheeler decided it probably was caused by a fission product. He selected three pairs of decay products, and he decided we should calculate how these would behave if they had a high cross section. We divided into three teams. I certainly was low man on the totem pole as far as knowing how to do it was concerned. It so happened I was part of the group which had the fission product that caused the problem, but we were so slow John and Charlie Wende finished up their products and they came over and worked over our backs. It was the xenon-135. We were starting to figure it out and would have gotten it by sundown. John, of course, had it, I‘m going to say in 15 minutes. If we had not been able to add more fuel, I’m certain we would not have been able to produce plutonium at the rate we had calculated, which was 250 grams per day per reactor.

Earlier, when the reactor was in the final design stage, George Graves, Greenewalt’s assistant director, and I were chosen to carry the news to the manufacturing director that there was a large probability that the reactor that was considered at that time would fail to operate at the design power of 250 megawatts. We suggested enlarging each one of the 1,500 fuel assemblies so that they would contain more uranium and expanding the number of fuel assemblies to 2,004. This required prompt action because the shield blocks through which the fuel was inserted were just ready for shipment to Hanford. Fortunately, this change could be made and the lost time was acceptable. The added fuel assemblies were what allowed us to overcome the later poisoning by xenon.

The first thing that gave Wheeler international attention was the development of the so-called Bohr-Wheeler theory. Niels Bohr of Denmark was one of the world’s top physicists and John had worked under him. After Bohr brought the news of fission to America in 1939, Wheeler saw Bohr and they decided this thing needed theoretical attention, and they put out a theory relating to atomic stability, a beautiful piece of theoretical physics. I’m biased, but I think John Wheeler’s analysis of the xenon poisoning at Hanford was in the Nobel Prize category. The problem appeared, it was solved, and we were going again.

I will give you an example of my social life during the time I lived at Hanford. John Wheeler and I decided to go to Priest Rapids and three of us walked to a point 16 miles from where we started. All we got to was a little knob of a hill. We started at 6:30 in the morning and got back at 8. We were in pretty good shape. That was a high point of my social life. We worked seven days a week. Another time John and I were out on a hike and I lost him in the lava fields. We got separated. I waited, thinking I have the brains of the entire organization with me and I lost him. Finally, I saw John walking about half a mile away. That was the most uncomfortable 90 minutes I ever spent. Another little story. Enrico Fermi and I shared an office in the 700 Area of Hanford for two months. You know when two people work in the same office they don’t always talk about work. Enrico one day pushed whatever he was doing aside and looked over at me and said, “Dale, did I ever tell you about how I got to come to the United States?” “Well, no, not really,” I told him.

When he was in Italy, he said, “I was a BEEG SHOT!“ He was what amounted to education minister in Mussolini’s cabinet. He had gotten word that he would win the Nobel Prize. He also knew his wife was one-fourth Jewish and he was afraid for his family and was looking for a way out. He went to Mussolini and said he was getting the Nobel Prize and this is a wonderful thing for Italy. It was like setting off a bomb under Mussolini, who asked if Enrico needed money. He said he had money and might sell some of his things, but would ask if he needed more. Enrico left Rome and took everything with him he could take, including his family. He got the Nobel Prize and the $50,000 check or whatever it was, got on a boat and came to the United States. End of story. That comes right from Enrico.

About the supposed friction between the academics and Du Pont. I am going to say there was absolutely none, but that isn’t quite right. The boys down the line, who had just gotten their Ph.Ds, with very little experience, were more inclined to be critical. I knew Wigner quite well, we got along famously. I’ll skip ahead several years. I was at Oak Ridge to see Alvin Weinberg. We were eating in the cafeteria and Eugene came in. I saw him standing there. I went over and said hello. He said, “Dale, I saw you sitting there and I was going to come over and say hello but I was afraid you wouldn’t remember me.” As sincere as could be. As if I could forget a Nobel Prize winner. The friction between the academics and Du Pont was about as important as that.

I didn’t see the Trinity test. I have never seen an atom bomb explosion and I am just as happy I haven’t. I know that after the bombs were dropped on Japan, I told my friends I would not have dropped it on a civilian population. I would have gone to the big mountain outside Tokyo and dropped one near the top and dropped another one about at the snowline where everybody in Tokyo could see it. I talked to Fermi about that and he said it was considered, but the reason they didn’t was that they didn’t have any extra bombs. They only had two and they would drop them where they meant business. I am not disagreeing but at the time I would not have done it if the decision had been mine.

Full Transcript:

S. L. Sanger: This is an interview with Dale Babcock on March 16, 1986 at his residence in Hockessin, Delaware, which is near Wilmington.

I spoke to Wheeler incidentally last week he got here, took your address. He is the one that told me about the article you’d written that he saw a definitive story on poisoning.

Dale Babcock: Yes, at the time that was written, much of the material that is in there was secret, and I tried to write around it so that what I was writing could be published in the newspaper. Any person who does that always runs into finding some things that couldn’t be done, so we had two choices. One of them was to change what I had written, and I did that in some cases. And the other was to declassify some of the items that I wanted to put in there. And as I remember, approximately half of the items were done one way and half the other. But nothing was left out that I considered was important in telling the story.

Sanger: Why don’t we maybe start—you can just give me your background, educational and with DuPont, and how you got into the Manhattan Project.

Babcock: Well that’s very, very simple. I went out to [DuPont’s] Experimental Station, which you undoubtedly know, in 1929 and then hired there from the University of Illinois. And my first assignment was under Crawford Greenewalt, who was directing a modest-sized group of engineers and chemists there, working in the general field of organic synthesis and separations of products.

I was a physical chemist and rather longhaired, I would say. And working in chemical engineers was—well, somewhat outside my field. After I learned that the only real difference in physical chemist and chemical engineer was speaking pounds instead of grams and a few other such things as that, I found no problem at all.

Sanger: You went to school at the University of Illinois?

Babcock: Yes, I got my PhD there in ’29.

Sanger: And you came to work then directly for DuPont though?

Babcock: That is correct. My entire technical career was with DuPont. The reason I mention Crawford Greenewalt: Greenie went up the ladder relatively rapidly and soon became the assistant director of the laboratory there. Then the war came on, was coming on, and the nylon business was certain to become an important item. I was transferred from the Experimental Station to work on nylon. Now then, this is about 1939 or thereabout. We certainly were not in the war as yet. Crawford Greenewalt had—I was under his jurisdiction when he was at Experimental Station.

Sanger: Nylon, development of nylon?

Babcock: Development of nylon. Of course, Wallace Carothers was the chemical spearhead. But I’m talking about other people that worked on that. I’m going to mention Hood Worthington, I don’t know why that name—

Sanger: Yeah, I have heard of him; he’s dead isn’t he?

Babcock: Yes, he died oh, ten years ago I think. He and I were transferred from Experimental Station to the nylon division. Now, there’s a difference between the experimental station corporate entity and experimental station area. They were both in the same area, but different corporate entity.

And Crawford Greenewalt had picked both of us to go over there, to leave. Then the atomic energy business came along, and Crawford Greenewalt was made one of the top people from the front company and he selected the people that he knew the best. And we were picked solely for that reason. He took us along with him.

I would like to digress for a minute and tell you how I learned of the atomic energy business.

Sanger: Sure, right. Fine.

Babcock: My background: I had been working at the Belle Plant, the DuPont Company that’s the ammonia department plant, trying to separate hydrogen from the mixture of coke-oven gas. And we used equipment that was designed largely for air separation. We of course had to go to lower temperatures by a good deal, and at that time we were operating at the lowest temperature, any place in the world, on the scale that we were operating. Many laboratories of course would consider a coolant, but we went down to about minus 205 degrees Fahrenheit to experiment, which is—no, minus 205 centigrade, that’s better.

With that as a background, the people at Columbia University, who had been attempting to get deuterium, heavy water, deuterium gas and separate it from the proteome gas, knew of this project. I was called to Columbia to talk to some of the people up there, which I did. And as a result of that—oh goodness, what’s the heavy water man’s name? The guy that discovered it?

Sanger: I can’t remember either.

Babcock: Well slip of the mind, it’ll come back in a minute. He came down to DuPont and discussed the subject of DuPont studying ways of getting deuterium on rather a large scale. And obviously I was a good candidate for that job, and was assigned to it strictly as a study proposition. And some people from the engineering department were working on it also.

Well, to make a long story short, it occurred to me that since the heavy water people were interested in something that could be done right away, time was of the essence, and it looked to me like that it was more to the point to get heavy water by distilling ordinary water than by distilling hydrogen gas, which I was the expert on and chosen to do because the distilling heavy water could be done with the equipment right off the shelf. In actuality, I don’t think that there was anything that we had to make that had been used for years before that. Well that was quite a break in the direction of things and the predecessor of—I don’t know what it was called. Well the government agency—

Sanger: Sort of the predecessor of the Manhattan Project —

Babcock: That is right, the predecessor.

Sanger: Office of Research and Development, ORSD. They called it the Uranium Project originally.

Babcock: The word “uranium” was up to this time had never been mentioned in my area. But they probably went around the corner and mentioned it.

Sanger: That was about when?

Babcock: This will have been in about, let’s say July of ’42. The war started in December of ’41.

Sanger: Yeah.

Babcock: And it was decided among Crawford Greenewalt and Compton was there and heavy water man, I still can’t think of his name, I’m very embarrassed about it. But anyway it was decided what I should do is write up a resume of the reasons for doing it, which I did, and a decision came along right away to go that route.

Well now then my background was not in that kind of thing at all. I had no expertise in running large installation units, fifteen feet in diameter and so on. Victor Thayer, who had been working along with me on this original project, was assigned the technical plan to carry out.

Well I went back to the nylon division. In about November of 1942 the DuPont Company had been asked by I guess the Manhattan District by now to look into the subject of making plutonium reactor. I’d better go back and finish up the heavy water story. The plant that I had suggested that they operate was built and actually operated and made heavy water in slightly over a year, and by another year something like thirty tons had been made and was then shut down. That was the heavy water that went up to Canada and it was eventually used in Canada for reactors.

Sanger: You had no idea what they wanted it for?

Babcock: At that time, I did not. I’m gradually getting up to what they wanted it for. Let’s see, we’re about in November of ’42. Crawford Greenewalt, Hood Worthington, Lom Squires, Will Hurst, and Monte Evans, those are names you probably have heard of before, those four including me, and Greenie is five. And he said, “I am going to describe to you people something that is heresy to chemists: we are going to make a new atom on the scale of pounds per year. The element was plutonium. That will, to a person in chemistry, that was heresy, absolute heresy. If he’d said, “Well, micrograms,” or something like that, there’d been no problem.

He then described to us what had been done by Seaborg and Compton and Fermi and this is being asked to go into this. He had been out to Chicago and talked to people out there. But this was merely something that people talked about and nothing would be done about it until further notice and go back and continue working in nylon. He then said that I believe it was on the second of December that a critical experiment was going to be conducted at the West Stands. That was given to me 25 years later.

Greene was out there at the time, was in the west end and saw the reactor go critical and then he came back and of course was all excited about it and the DuPont Company was asked to either go into it or study critically the going into it. At about that time I guess I was taken out of the nylon division and put on this full time—kind of more of a paycheck came from that. I was given the job of being the liaison between the DuPont Company and the Chicago in the area of physics. And my first trip out there was in — it was after Christmas and before New Years.

Sanger: To Chicago?

Babcock: To Chicago, to the West Stands. I saw the reactor and saw the control.

Sanger: Oh did you?

Babcock: Greene and I were there together and we got all the brass—let’s see Wally [Walter] Zinn was there and Fermi and whatnot and one of the items that I expressed great concern over was how we could keep things from getting out of hand. And Enrico said why it’s no problem at all, sit down and run it. And they said it’s indicated about one on the scale right now, bring it up to five and there. Well that’s something you don’t like to do.

Sanger: This is on the first one, CP-1 you’re talking about?

Babcock: That is exactly right. My own opinion of it was I was going to do it and I was going to do it correctly and it took me all day to get it out there, so what. I might overshoot it, but as I remember I took about three or four minutes to get that onto a five-level and Fermi’s words were “You are indeed a very careful young man.” Now he was complimenting me of course and I was not very much younger than he.

Sanger: How old were you then?

Babcock: Oh that was 1942 and I was born in 1906; you can figure it out for yourself. I was a little bit older than Wally Zinn.

Sanger: About thirty-five, thirty-four or thirty-five.

Babcock: Well needless to say things happened very, very rapidly from that minute on. DuPont was asked to build a plant and operate it and engineering department had to be brought in and geared up and most of the technical people had to get organized and taught—I was directing in Wilmington a group of physicists and engineers; Charlie Wende, a name you probably heard.

Sanger: Yeah I’ve heard of him.

Babcock: And John Wheeler, Paul Gahst, Kelly Woods; I think there’s about a dozen but that dozen didn’t stay very long; it was a different dozen all the time, people were going other places. We of course were greatly concerned over the problem of criticality. You understand that term?

It really had to do with the number of atoms that were inside a nuclear reactor that didn’t contribute to the reaction itself either by being a part of the reaction or the slowing down of neutrons. Obviously we had to have water in there the way we had it designed. We had to have aluminum in there, there had to be control rods in there, such things like that. But we were operating on a very, very thin margin.

The “excess k” is a term that I’m going to bring up now and that is the percent of neutrons that are in excess of what was needed to maintain chemical reaction. That number has to be a small positive number; 0.0001 is enough but you won’t do very much at that rate.

Sanger: In other words that’s over the one?

Babcock: That’s over the one and over the one enough that it can take care of temperature coefficients take care of everything that goes on there. It was an operating reactor, as I said.

Well John Wheeler, when he was out at Chicago, had that same worry. Everyone has that worry, but he had done a bit of a study and calculation on it. As far as I know, he was the only one that had taken that as a major job and had done something about it. He, for example, calculated that the cross section of the material that was in there that we didn’t know about—I’m speaking right this minute about fission products that are formed in the reactor—the cross section of any one of the fission product atoms had to be less than about 150,000 barns. I’m sure the terms “barns” you are familiar with?

Sanger: I’m no scientist but I picked up some of these terms reading about it.

Babcock: Well of course that gives you a ballpark figure as to what you’re looking at. Now then to give you some more numbers along that line, the cross section of the highest known atom at that time was about 50,000 barns. In other words, as long as it didn’t exceed by very much the cross section of any known atom fission products were not a critical item. But if they exceeded this 150,000 barns—I’m jumping ahead of the story now but Xenon, which turned out to be a fission product of high cross section had a cross section of about 3.5 million barns, completely unheard of, unpredicted—I’m going to quote Fermi on that. It was almost an impossibility that that could occur. I’m sure that he didn’t mean it quite the way I remember him saying it but at any rate, it was a surprise to everybody.

John was working on that general subject and he and I decided that—I use this term he and I, John and I, big John and little D—we used to go down to Oak Ridge and talk to the people down there who were running a nuclear reactor and to see if by any chance we could pick out the growth of this material in their reactor and find out what was happening. It sounds like a straightforward and easy thing to do. You either find it or you don’t.

Well we went down and we were received very, very well but I think the reason that we were completely unsuccessful was that the operators of the nuclear reactor down there were a bit embarrassed about the lack of calibration of their mechanism for measuring what we were talking about. In other words, we were interested in what happened when it shut down and when it started up. And getting the reactivity during those periods was not easy to do and they hadn’t thought it was particularly important until we discussed the subject with them. And we got absolutely nothing out of it.

Now then that means that they had no data that was really related to it but it doesn’t mean that there wasn’t data there that we weren’t doing something about. Now then the problem is what should I do? I am sure I had enough gold braid on my shoulders to insist that something be done about it. I made enemies and that’s one thing you can’t afford to do in a situation such as that. We had to work with people down there and I wanted to be their friend so I already was, so I decided that I would not make any waves about it. I don’t know yet whether it was the correct decision or not, but there it was. That subject was still looked at by John every now and then but it more or less died; we had too many other things to worry about.

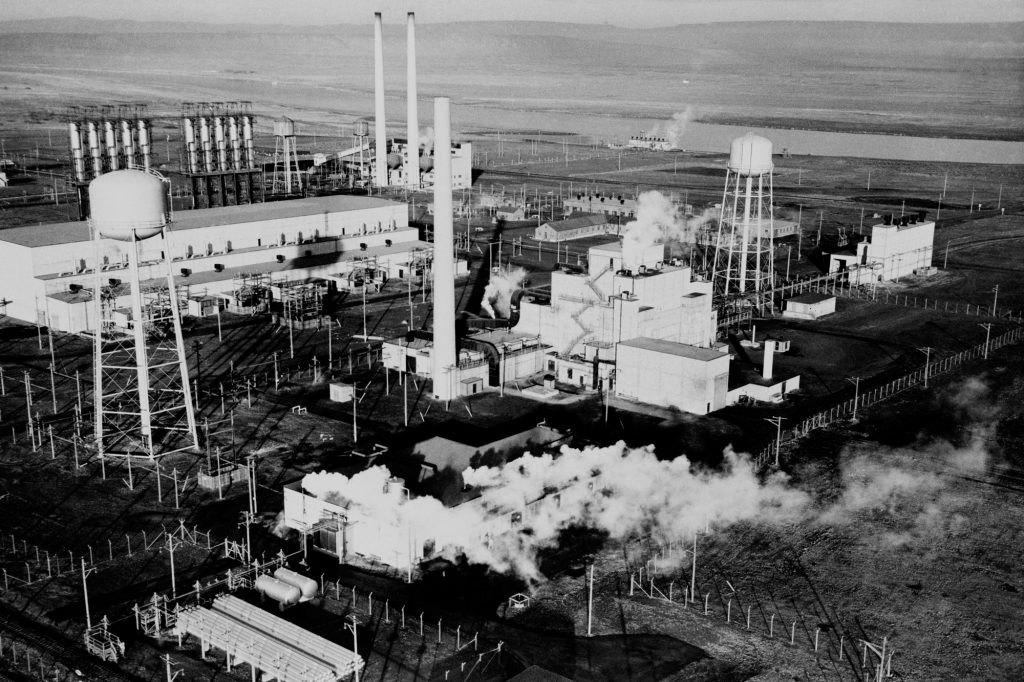

Now then I’m sure that this goes into where I’m talking into that article that you were writing. Anyway I will give you a little bit more than what’s given in there. The nuclear reactor that was started at Hanford in ’43, ’44 I guess, died almost right away. And John Wheeler who was on the site at the time, with not too much studying, decided that it probably was [caused] by a fission product. And that it had to have a certain half-life, which he said had to be of the order of about twelve hours. And it had to be a fission product and then a daughter product, which decomposed from the primary product. The daughter product had to be the one that had the high cross-section.

He selected three pairs of decay products, that as near as he could tell, all three fit the evidence that we had before us. And he decided that what we should do would be to calculate out how these would behave if they had a high cross section. We divided the group into three parts and I certainly was the low man on the totem pole as far as knowing how to do it was concerned, but I headed one group and John Wheeler headed the second group and Charlie Windy headed the third group and it so happened it was the group that I was working on was it. But we were so slow that John and Charlie finished up with their products and came over and they were working over our backs and they said, “Do it this way” and that was the xenon.

Sanger: Your group had the xenon to study?

Babcock: I was head of the group; yes. There was the small group and Paul Gahst and I were working together and we were starting on it and we would have gotten it I’m sure before sundown but I don’t know how much before and John of course, had it in I’m going to say fifteen minutes. Did you have the graph? I’ll show you.

Sanger: Yeah.

Babcock: There should be a graph.

Sanger: Yeah there is.

Babcock: It’s this decay, which doesn’t show very well. This scale has to be expanded out in here but it’s that decay curve that we were trying to duplicate by showing that we were losing reactivity and this is over a time of fifteen hours or something like that, which is well within the half-life that we were talking about earlier. But anyway I well remember I was reduced to the business of plotting the data, which I was very glad to do and I put those points in there just like that and when we weren’t deviating from the line we actually had on there we knew that we had it. Those are some of the joys of being a scientist—seeing that kind of thing come out and of course we didn’t know at that time whether they’d be able to get around it or not, but we did. I’ve gone on and I’ll let you ask me some questions.

Sanger: One thing I wondered if you hadn’t been able to add the fuel tubes to the reactor what would have happened do you suppose?

Babcock: You’re talking about the corner?

Sanger: Yeah if they hadn’t been added I mean earlier?

Babcock: That is not an easy question; we thought about that a great deal. It is absolutely certain that we would not have been able to produce plutonium at the rate which we had calculated we should, which was 250 grams a day per year. Now then, would it have been 200 grams a day or 100 grams a day? The number that I come up with is probably not more than 100 grams a day until we found ways of getting burning out some poisons that were in the reactor such as the [inaudible] that was in the graphite and that burned out and you gradually got more.

Sanger: So you would have had to run it at a lower level basically?

Babcock: You would have to run it at a lower level and if I say 100 megawatts and someone else says 200 megawatts I’m not going to argue with them at all. I would argue with them though if they tried to go below fifty megawatts.

Sanger: Is it considered any one person decided to add those tubes in the design?

Babcock: Would you like to hear that story?

Sanger: Yeah why don’t you tell me that? Is it George Graves?

Babcock: Yes that is right. I’ll give you the organization now, Greenewalt was the technical director and George Groves was his assistant. Again George Groves, Crawford Greenewalt, Edward Worthington, Dale Babcock had started out together at experimental station ten years before. We all knew each other; we all had widely different backgrounds.

John Wheeler and I wrote the letter which is referred to in the [inaudible] at about the time that something should be done about it in order to mesh in with the changes that had to be made without causing a complete upsetting of the apple cart. Of course we didn’t know that we were on to something that had to be done and we had a lot of other things to do too, but I didn’t push it as hard as I should have. We’d already made an attempt to measure down at Oak Ridge.

But at any rate it had been discussed with George Graves and it had been discussed with Crawford Greenewalt probably in the same meeting—we had a meeting about once a week and we brought up such subjects as this. And we generally got the answer: “Well yes, that’s important, we got other things we have to do right now and we don’t need to do anything yet, and bring it up again.”

Well I brought it up. The reason I say I brought it up—that is correct—but I would say that John Wheeler was urging me as much as possible and we were at about the time when the shield blocks had been made and were ready for shipment to Chicago. Our recommendation was that we would bore the holes in the shield blocks that we hadn’t planned to do and also that all the holes that had been bored in there to put the fuel tubes in being enlarged by eighty millimeters or something.

Now then, that has to be done at the factory. And once they’ve been shipped out to Hanford, you had it. There is just no way of getting a construction crew to cope with that kind of delay or reasons that aren’t very good. I don’t know who made the decision; it was probably George Graves that we would talk it over with manufacturing as soon as we could get a date to talk to them.

Well now then Crawford Greenewalt was gone and George Graves of course took over as head of the technical division and I moved up to his position I guess you might say and we were talking with Monty Evans and Joe Tully. Monty Evans was the director of manufacturing and Joe Tully was his assistant or down the line a little ways. It was just the four of us and it was Saturday afternoon and there was very few people around and I gave, as I remember, a twenty minute outline of the problem as we saw it and how severe it was and what had to be done and what we thought we would gain by changing the shield block specifically, that’s the thing that you were talking about.

As I look back I think I gave a good and fair description of the problem, maybe I’m bragging. But the manufacturing people were only half way convinced that they should do something about it and it was left that what they would do Monday morning would be to get with the manufacturers of the blocks and tell them what we’re talking about and get them to predict how long a time it would delay the shipment of the shield blocks.

Well of course I can’t ask for anything any better than that; if it’s a year you’re not going to do it, if it’s a few days well then there’s no argument. I think the word came back that they could do it in a week and manufacturing then made the decision I think on Monday morning or Tuesday or whenever it was after talking with them that, yes, we were going to go that way.

And needless to say I wasn’t a popular person around the manufacturing division group for several weeks after that largely because dammit, I had added another week and that’s all there is to it and they were not very agreeable to that kind of thing. But there was no hard feeling and it was always Monty and Dale and that kind of thing but I didn’t feel too good about it.

Sanger: What did you tell them? Do you remember just briefly what the problem was, why this had to be done?

Babcock: Well what we said was that we were gradually losing nuclear reactivity by other things that the engineering department and other people were doing to the reactor, putting the extra holes in to put instruments through and putting in safety rods and all of that, we knew that they were going to be there but they put in larger sizes and all that. So we needed extra reactivity in order to take care of just ordinary little things that happened in construction.

We had figured that tube size would be a certain amount and it turned out that it was that but on average it was a little bit larger than that, not enough but enough to increase the amount of aluminum in there by the amount that we hadn’t made an allowance for; it’s that kind of thing. And it was just these niggling little things that keep adding up; nothing ever happens favorably. And we said that doing what we were talking about, adding reactivity to the reactor, like putting money in the bank, you could spend it any way you wanted it if you had it but if you didn’t have it you were in this sorry state.

And I’m sure that manufacturing people understood that as well as we did. The only question is it was their ox that was being gored instead of us; they were the ones responsible for getting this thing going in how many ever days they had. But it gave us enough to overcome the xenon that was introduced in by operating at about 200 megawatts and then we crawled from 200 on up to 250 and not as fast as we could have but we were burning out the poisons. The numbers are given in there but as I remember we gained about a tenth of 1% in nuclear reactivity.

Sanger: By adding those tubes?

Babcock: By adding those extra tubes.

Sanger: And that’s all, huh?

Babcock: Yeah but don’t look down your nose at a tenth of 1%. The total amount of extra reactivity we had there at any time was 2%.

Sanger: Oh is that right?

Babcock: That’s all there was and that we had to put water in and a lot of other things.

Sanger: And that 2% was about as much as you could expect, huh?

Babcock: 2%. If you’re going to build a reactor and its got carbon and all things like that, 2% is all the extra reactivity that’s in there.

Sanger: I know what a control rod is but what’s a safety rod?

Babcock: Well a control rod is merely a rod that has atoms of boron in it that absorb a lot of neutrons. The control rod is meant to come in from the side of the reactor, as I remember there were nine of them and they were manually controlled. You could put them at any place you wanted to in there.

The safety rods were to shut the reactor down rapidly no matter what happened—lost water out of the reactor that gained extra activity—no matter what happened, we had to be able to shut that reactor down very, very rapidly. We’re talking about seconds now. I remember they dropped down a distance of about thirty feet and the limit on it was down to within a foot of the bottom in two seconds, now it might have been three.

Sanger: What were they made of?

Babcock: The safety rods were made out of boron steel.

Sanger: So similar to that the control rod?

Babcock: Similar to the control rods except the control rods were made out of lithium aluminum. Maybe it was boron aluminum, I think it was boron, it doesn’t really make a difference.

Sanger: What confused me was that I read an article by this Henry Newsome who compared the safety rods to an accelerator in a car, which I didn’t understand that because he said the control rods were like the brakes and the safety rods were the accelerator it seemed like they were both like brakes.

Babcock: That’s right, I don’t remember that article. It’s a poor choice of words.

Sanger: Yeah that’s what I thought because you didn’t use the safety rods, did you except in an emergency or if you wanted to keep it completely shut down or what?

Babcock: In general we like to test things and we didn’t want them sitting around getting dust on them and not using so almost every time the reactor was shut down we did what is called SCRAM, a shut down in a hurry; so we dropped all the safety rods in.

Sanger: Okay well that’s just kind of a digression, but I was curious.

Babcock: That’s an item that you have to understand. As I remember there were twenty-nine rods.

Sanger: They were generally above it where they could fall from gravity?

Babcock: They were above and they were hooked onto a winch mechanism and the winch unwound and a steel cable lowered them into the reactor.